MEDIUM-DUTY TROLLEY OPERATOR

The GCL-MT is designed for standard-lift sectional doors that have a limited-duty cycle requirement. Advanced features and robust mechanical design combine to provide a medium-duty operator that is the new benchmark in the industry.Contact us about this product

- 11.5 inches per second door speed.

- Optical limit system with linear travel nuts.

- Max run timer automatically adjusts to up and down run time.

- TensiBelt® primary reduction.

- Delay on reverse.

- 16-character LCD display.

- UL325-2010 approved.

- Drawbar disconnect for emergency manual operation.

- 3-button control station.

- 2-year/20,000-cycle warranty.

- Programmable mid-stop.

UL325-2010 APPROVED

- Allows for monitored entrapment connections for protection and momentary operation when used with select photo eyes and/or edge-sensing devices.

- Approved monitored devices

GCL-MT Advantages

- Rated for 15 cycles per hour operation. Maximizing the performance of a medium-duty operator.

- Modular design with optional expansion boards for advanced timer to close, and auxiliary output functionality.

- Optional Intellicode® plug and play receiver learns up to 50 transmitters. Learn and delete individual transmitters directly from LCD display.

- TensiBelt® primary drive reduction eliminates need to adjust belt tension.

- Available in either 115V or 230V AC 1Ø 60Hz. Expanded offering increases applications available for medium-duty use.

- Motor with built-in thermal protection and ball bearing drive end. Provides overload protection and bearings extend life of motor over typical bushings.

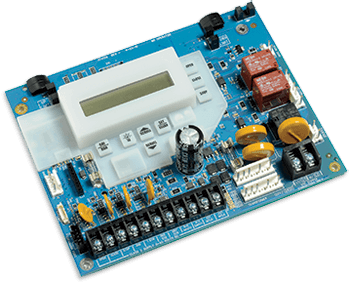

- LCD display with intuitive setup menu. Provides real-time status and trouble-shooting assistance.

- Open/close/stop and setup keys included on control board. Keeps all controls near the LCD display convenient for set up.

- Motor

1/2 HP, AC capacitor start/run motor. Motor replaceable without changing limits. - Drive

- Primary - TensiBelt® auto tensioning poly-V J-belt.

- Secondary - Chain and sprocket reduction

- Friction Clutch

Adjustable clutch to help protect against door and operator damage. - Precision Radial Ball Bearings

Incuded in critical areas throughout the powertrain. - Rail Assembly

2" door track with nylon rail runners and chain guides. - Pre-wired to accept:

- Monitored entrapment device such as photo eyes.

- Single or 3-button control stations.

- External interlock switches.

- Brake

AC solenoid actuated band brake. Must be ordered from factory. - Timer to Close Module

Timed close set via the LCD display from 2 seconds up to 5 minutes. Includes pre-close warning contacts, timer hold input, auxiliary open input, normally closed safety input, and monitored edge input. - Auxiliary Output Module

Provides relay contacts at the open, close, and mid-stop limits. Contacts for 5-minute lamp, and "ADA" contacts set via LCD display to warn during opening, closing or both. - 315Mhz Receiver Module

Intellicode® radio receiver that is 315Mhz and capable of storing 50 single-button and/or 50 open-close-stop transmitters with the ability to add and/or delete transmitters individually, identify and store activating transmitter ID(s). - UL325-2010 Approved Reversing Devices

The installation of a monitored external entrapment device is required for momentary contact close operation on all commercial door operators. Only the following devices, when purchased through Genie, are UL-approved for use to meet this requirement:- Safe-T-Beam® Photoeye Kit with adjustable bracket P/N 38176R.S1

- Impact-protected Commercial Photoeye Kit P/N OPAKPE.S

- MillerEdge ME/MT/CPT (DC or T3) 2-wire edge sensor. Must be used with TCM (OPABTCGX.S) or Interface Module (OPAKMEIGX.S).

- NEMA 4 Photoeyes P/N OPAKPEN4GX.S

1 — Default device when operator is ordered.